Supper Heavy-duty (Max. dia.650mm)

3+1 Guideway

Features:

1) Super Heavy-duty, Machine bed was built with 3+1=4 guideways

2) The auxiliary guideway available for automatic pneumatic clamping/unclamping by CNC control

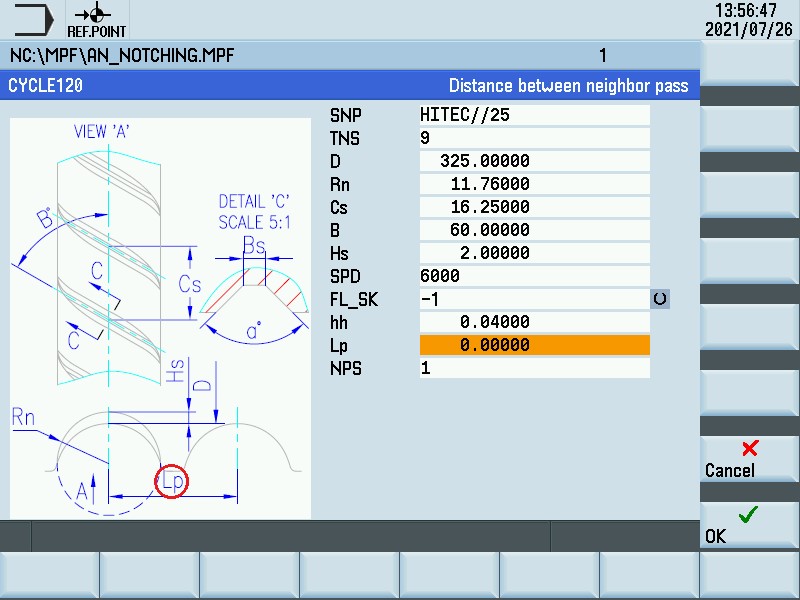

3) Smart Software for very Simple & Easy operation.

4) Just input Few Data like roll diameter, groove radius, rib space etc. in the Graphic interface of CNC,

CNC will create the working program by CNC itself, no need the operator to do any complex programming.

5) Automatic centering & measuring device as standard accessories

6) Oil-Air mixture cooling to the tip of notching tool & marking tool for best cooling. No bad smell from diesel/kerosene.

7) European type tooling system for smooth & best finishing for notching & marking.

8) Remote diagnosis for trouble shooting; remote communication for softwear upgrading

TECHNICAL DATA:

s/n | Model / Item | CRM610HD |

1 | Max. roll diameter | 600mm (650mm/optional) |

2 | Max. roll length | 2500mm |

3 | Max. roll weight | 3500kg |

4 | Number of guide way in bed | 3+1= 4 pcs. |

5 | Type of guide way | Rectangle |

6 | Width of bed (Top) | 820mm |

7 | Width of bed (Bottom) | 900mm |

8 | Automatic Centering Device (ACD) | Full-Auto |

9 | Country of origin of ‘ACD’ | Japan made |

10 | Automatic ‘Oil-Air Combination Cooling Unit’ (AOAC) for Notching & Marking | √ |

11 | Automatic lubrication pump (Capacity) | 2 Liters |

12 | Cantilever mobile CNC operation stand/box (DesTech) | √ |

13 | Industrial class air exchanger for electric cabinet (Brand: WORLDER) | √ |

14 | Motorized Tailstock movement | √ |

15 | Bed guide way protection telescopic cover | √ |

16 | Worm Gear in headstock – Material | Tin Bronze |

17 | Worm gear for swivel marking head | Tin Bronze |

18 | Diameter of worm gear for spindle | Dia.400mm |

19 | Number of teeth of worm gear for spindle | 96 teeth |

20 | Center height of spindle over bed | 600mm |

21 | Tailstock type (Heavy-duty) | Dual lock |

22 | Taper of spindle - Tailstock | Morse 6 |

23 | Taper of spindle - Headstock | Morse 6 |

24 | Max. swivel angle of marking head | +/- 45° |

25 | Type of notching head (Rigidity) | Fixed |

26 | Type of center against notching tool holder (arbor) | Live center |

27 | Notching rebar diameter range | 6-80mm |

28 | Available notching of roll material | SG/HSS/TC |

29 | Available font of marking/branding | At will |

30 | Longitudinal movement alone bed | Automatic |

31 | Accuracy grade of ball screw- Transverse movement | P3 / p4 |

32 | Accuracy grade of ball screw- Longitudinal movement | P3 / p4 |

33 | Bearings for ball screws | NSK |

34 | Notching per roll | Free choice |

35 | Notching angle | Free choice |

36 | Omitting ribs | Free choice |

37 | Minimum feed unit | 0.001mm |

38 | Minimum feed unit | 0.001° |

39 | Max. spindle speed of notching head | 550rpm |

40 | Max. spindle speed of marking head | 2850rpm |

41 | Spindle bore of headstock: | MT#6 |

42 | Headstock chuck (4 jaw chuck) | 400mm |

43 | Motor of swivel head (AC) | 1.1kw |

44 | Workpiece swivel feed speed | 50°-600°/Min. |

45 | Rapid workpiece feed speed | 4000°/Min |

46 | Swivel speed of swivel head | 40°-600°/Min. |

47 | CNC controller (SIEMENS) | 808DA |

48 | C axis servo motor (Notching axis & Marking axis) | 3.5KW |

49 | Y axis servo motor (roll rotation axis) | 2.0KW |

50 | C axis servo motor (Cross feed axis) | 2.0KW |

51 | Z axis servo motor (Longitudinal axis) | 1.75KW |

52 | Output torque of servo motor (C axis) | 16.7Nm |

53 | Output torque of servo motor (Y axis) | 9.5Nm |

54 | Output torque of servo motor (C axis) | 9.5Nm |

55 | Output torque of servo motor (Z axis) | 8.4Nm |

56 | Type of servo motors | Absolute value |

57 | Brand of all cables between servo motors & servo drivers | Siemens |

58 | Brand of power cables for CNC - 5m; 7m; 10m | Siemens |

59 | Brand of cable PPU to V70 - 3m | Siemens |

60 | Brand of CNC panel | Siemens |

61 | Brand of emergency button | Schneider |

62 | Brand of all contactors | Schneider |

63 | Brand of all relays | Schneider |

64 | Brand of all breakers | Schneider |

65 | Brand of all incr. encoder cables | Schneider |

66 | Brand of switch power supply | Schneider |

67 | Number of transformers | 2 pcs. |

68 | Overall dimension: Approx. (mm) | 4000x1850x1850 |

69 | Packing size of machine (L*W*H) Approx. (mm) | 4660x1950x2150 |

70 | Net Weight (Approx.) | 6500kg |

71 | Gross Weight (Approx.) | 7000kg |

If you need more detail information, or technical discussion for best solution to your working jobs,

please feel free to write us at

technical@hitecindustry.com; service@hitecindustry.com; or sales@hitecindustry.com

Copyright © 2021 Hitec Industries Co., Ltd. All Rights Reserved 苏ICP备13031421号-1 Powered by:www.pai-du.com